The American Alligator is a very valuable natural resource in Louisiana. From its rugged hide is made some of the most elegant and expensive leather products in the world.

Quality is a must to any customer willing to buy alligator products that cost several hundred to several thousand dollars each. Such an investment is made only in products that meet high standards. That commitment to quality must start with the trappers who harvest the alligator and must be shared by the helpers and processors who skin the hides.

Quality is a must to any customer willing to buy alligator products that cost several hundred to several thousand dollars each. Such an investment is made only in products that meet high standards. That commitment to quality must start with the trappers who harvest the alligator and must be shared by the helpers and processors who skin the hides.

History

Much has changed in the leather markets since the 1930's when E. A. Mcilhenny described how trappers, who were not paid any more for a twelve foot skin than for a seven foot skin, would cut the larger hide into two.

" In other words--If a hunter kills a twelve foot alligator he cuts the skin so as to get two seven foot pieces from the one by cutting the skin in a diagonal manner from a point forward of the front leg to such a point on the tail that it will net him seven foot pieces, and the buyer pays full price for two seven foot skin." E. A. McIlhenny

It was common practice even into the early 1980's for buyers to round down the length of alligator hides to the nearest foot if the extra inches didn't total at least six, and in some instances ten inches. Today, buyers pay to the inch, and the importance of increasing the quality of salted alligator hides can't be stressed too much.

Hide Care Tips

Most current quality problems with Louisiana alligator hides can be cured by simply using extra care with the skinning knife and extra effort with the hide scraper.

The Right Tools

|

Skinning Steps

|

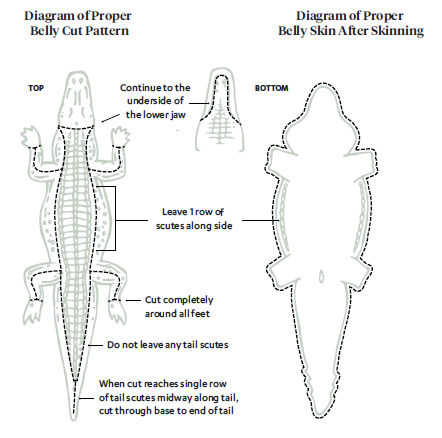

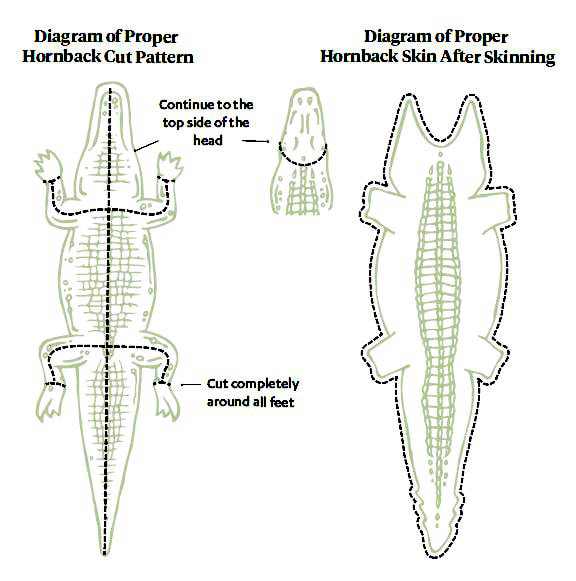

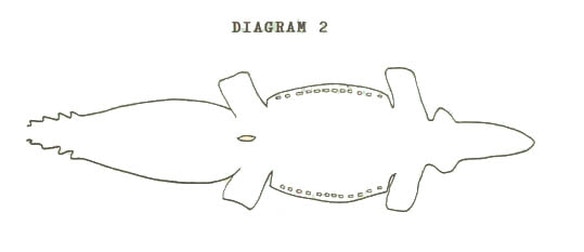

The area between the neck and vent in Diagram 2 is the part of the belly hide that is graded. Holes or cuts in this part of the hide make it difficult or impossible to cut full belly patterns for purses, briefcases or larger leather articles. Enough holes or cuts in the flanks can even make cutting shoe vamps or smaller leather-goods difficult. The one row of scutes along the sides of the alligator are left so the tanner has some extra hide to tack to when the hide is stretched and dried during the tanning process. Special care should be taken not to cut or put holes in the belly pattern of the hide (particularly around the legs and flanks where the thin hide is easy to nick with a knife).

Proper care of alligator hides begins as soon as the animal is harvested. Removing meat and fat from the hide is very important because of the time necessary to store and ship alligator hides overseas for tanning. This often takes several months and the -excess meat simply helps bacteria get started and can lead to "red heat" or " slipping" scales. If excess fat is not removed it can prevent salt from properly penetrating the hide. Also, if the fat heats up, it can actually penetrate the hide and leave grease spots on the finished leather.

|

Curing

The purpose of curing alligator hides is simply to remove moisture from the hide so it can be better preserved before tanning.

Method 1: Salting

A fine grain mixing salt works best and is the preferred method of curing alligator hides. Salt should be applied generously (1/2 to 1 inch thick) and rubbed into all parts of the hide.

Salt should be rubbed thoroughly into the hide, making sure enough salt gets into the creases, flaps, tail and similar places where bacteria can get a start. Salt helps slow bacterial growth. Tightly roll the hides and stack in a well-ventilated place where they can drain. After three to five days in a cool or shaded place, the hides should be resalted for best curing. Don't use rock salt and don't freeze hides (freezer burned hides won't tan properly).

Method 2: Brining

If done correctly, a brine solution for both curing and storing alligator hides is an acceptable way to handle them. But close attention must be paid to keep the brine saturated with salt and hides should be checked frequently to assure proper curing.

Method 1: Salting

A fine grain mixing salt works best and is the preferred method of curing alligator hides. Salt should be applied generously (1/2 to 1 inch thick) and rubbed into all parts of the hide.

Salt should be rubbed thoroughly into the hide, making sure enough salt gets into the creases, flaps, tail and similar places where bacteria can get a start. Salt helps slow bacterial growth. Tightly roll the hides and stack in a well-ventilated place where they can drain. After three to five days in a cool or shaded place, the hides should be resalted for best curing. Don't use rock salt and don't freeze hides (freezer burned hides won't tan properly).

Method 2: Brining

If done correctly, a brine solution for both curing and storing alligator hides is an acceptable way to handle them. But close attention must be paid to keep the brine saturated with salt and hides should be checked frequently to assure proper curing.

Brine PreparationIngredients 50 gallon covered plastic drum 50 pounds of salt 1 pound of 20 Mule Team Borax (boric acid) 1 pint bleach 25 gallons water |

In order for brine solutions to be effective they must be carefully prepared and maintained. A plastic or other non-corrosive covered container of sufficient size should be used. Heavy, 50 gallon plastic drums used for shipping olives, peppers or pickles are best, but large plastic covered garbage cans are good substitutes. The brine solution must remain saturated with salt. Too little salt in solution will cause the loss of hides. Fill container half full of water, add salt, borax and bleach to drum and mix thoroughly. After complete mixing a 2 or 3 inch layer of salt should remain on the bottom. The bleach and borax will assist in keeping bacterial growth to a minimum.

Alligator hides are sensitive to many chemicals which may affect the tanning process. When it comes to chemicals, more is not better. DO NOT add formaldehyde or other chemicals which may affect the hide.

Hides should be properly scraped and salted with a one inch layer of salt, tightly rolled and secured with a rubber band prior to placing in brine. When submersing a hide in the brine it should be rotated to allow most of the air pockets to escape. If properly salted, the layer of salt in the rolled skin will act as a wick to draw the brine solution throughout the hide. All hides should be entirely submersed in the brine at all times. Each time a hide is added to the brine a few pounds of salt should be sprinkled over the top. This is important to maintain the saturated solution.

The brine container should be kept tightly covered to keep insects and airborne contaminants from entering. When hides are to be delivered for sale they must be removed from the brine and entirely resalted prior to being shipped or placed in refrigeration.

Alligator hides are sensitive to many chemicals which may affect the tanning process. When it comes to chemicals, more is not better. DO NOT add formaldehyde or other chemicals which may affect the hide.

Hides should be properly scraped and salted with a one inch layer of salt, tightly rolled and secured with a rubber band prior to placing in brine. When submersing a hide in the brine it should be rotated to allow most of the air pockets to escape. If properly salted, the layer of salt in the rolled skin will act as a wick to draw the brine solution throughout the hide. All hides should be entirely submersed in the brine at all times. Each time a hide is added to the brine a few pounds of salt should be sprinkled over the top. This is important to maintain the saturated solution.

The brine container should be kept tightly covered to keep insects and airborne contaminants from entering. When hides are to be delivered for sale they must be removed from the brine and entirely resalted prior to being shipped or placed in refrigeration.

Take Special Care:

If any "red heat" or "slipping scales" are noticed in a trapper's lot, the hides should be separated from the rest of the hides and treated in a solution of water, bleach, tide and borax. This "slip dip" is made by mixing a half gallon of bleach in 25 gallons of water and adding half a regular size box (about one pound) of Tide and Borax. The salt in an affected skin should be discarded. (Red heat in particular can spread from one hide to the next). Hides should then be submerged in the dip about 15 minutes. Drain the skin and liberally resalt. Re-roll the hide and if possible, store dipped hides away from other skins.